Casting motor housing

- Code product: TD01

- Manufacture: TNGEC

Description Information

The TNGEC electric motor housing is made of cast iron with good strength and heat resistance. The casting process is carried out automatically using Furan sand casting technology and the DISAMATIC line from Denmark, helping to ensure high accuracy and uniform quality of the product.

Gang Thep Engineering Joint Stock Company (TNGEC) is one of the leading manufacturers of electric motor housings in Vietnam. With the automatic casting line using Furan sand casting technology and DISA MATCH, TNGEC can produce electric motor housings in large quantities, with high durability and stability, and low cost.

TNGEC electric motor housings are used in many fields such as industrial machines, construction, agriculture, etc. The products have high durability, stability, and low cost, meeting the needs of domestic and international manufacturers.

TNGEC electric motor housing

Some outstanding advantages of TNGEC electric motor housings:

High durability: TNGEC electric motor housings are made of high-quality cast iron, with good strength and heat resistance.

High stability: The casting process is carried out automatically using Furan sand casting technology and the DISAMATIC line from Denmark, helping to ensure high accuracy and uniform quality of the product.

Low cost: TNGEC electric motor housings are mass-produced in Vietnam, with a lower cost than imported products.

TNGEC is a OEM manufacturer in Vietnam and is a direct supplier of products to Toshiba Corporation in Japan.

Products are manufactured to order on a complete DISAMATIC automatic casting line:

Introduction to Furan sand casting technology at TNGEC:

Furan sand casting technology is a metal casting process that uses unfired sand molds to create high-precision metal products. In this process, sand is mixed with Furan resin and a catalyst, then poured into a mold. The Furan resin then hardens and creates a strong mold that can withstand the high temperatures of the casting process.

Furan casting technology uses a synchronous, automatic high-precision molding line to create castings with high-quality and smooth surface finishes.

Advantages of Furan sand casting technology

Furan sand casting technology has a number of advantages over other casting methods, including:

- High precision: Furan sand casting molds have high precision, which helps to create products with high precision shapes and sizes than products cast by other methods, as the casting mold is made of strong sand that does not deform.

- High durability: Products cast by Furan sand casting have high durability and can withstand high pressure and temperatures.

- Flexibility: This technology can be used to cast products with complex shapes, as sand can be poured into molds of any shape.

- Suitable for a variety of metals: Furan sand casting can be used to cast a variety of metals, including cast iron, steel, copper, aluminum, etc.

- High production capacity: This technology can produce products at a faster rate than other methods, as the casting mold made of sand can be reused multiple times.

- Environmentally friendly: Furan sand casting is an environmentally friendly casting method that does not use harmful substances.

Furan sand casting equipment line at TNGEC

TNGEC uses an electrically powered Furan sand molding line manufactured by Omega Sinto Foundry Machinery in the United Kingdom.

Equipment line:

No | Equipment | Quantity |

I | Mixer |

|

1 | 4-way pneumatic sand gate | 1 |

2 | Spartan 310P mixer | 1 |

3 | Model J vibration compaction mold table | 1 |

II | Recycling equipment |

|

1 | Gamma 6LL sand breaking and recycling equipment | 1 |

2 | Vator 6 vibrating sand lifting ladder | 1 |

3 | Dust separation and sand cooling equipment | 1 |

4 | DP100 pneumatic sand transport tank | 1 |

5 | Control panel | 1 |

Technical specifications:

Compressed air | 0.11 Nm3/min |

Mixer rotation range | 2700 |

Outlet height | 1.350 mm |

Sand feed mouth height | 2.079 mm |

Number of pumps | 2 |

Mixing capacity | 5-10 tons/hour |

Mold mixing technology | Furan |

Mixer shaft speed | 534 rpm |

Mixer trough length | 1.690 mm |

Mixer motor power | 4 kW |

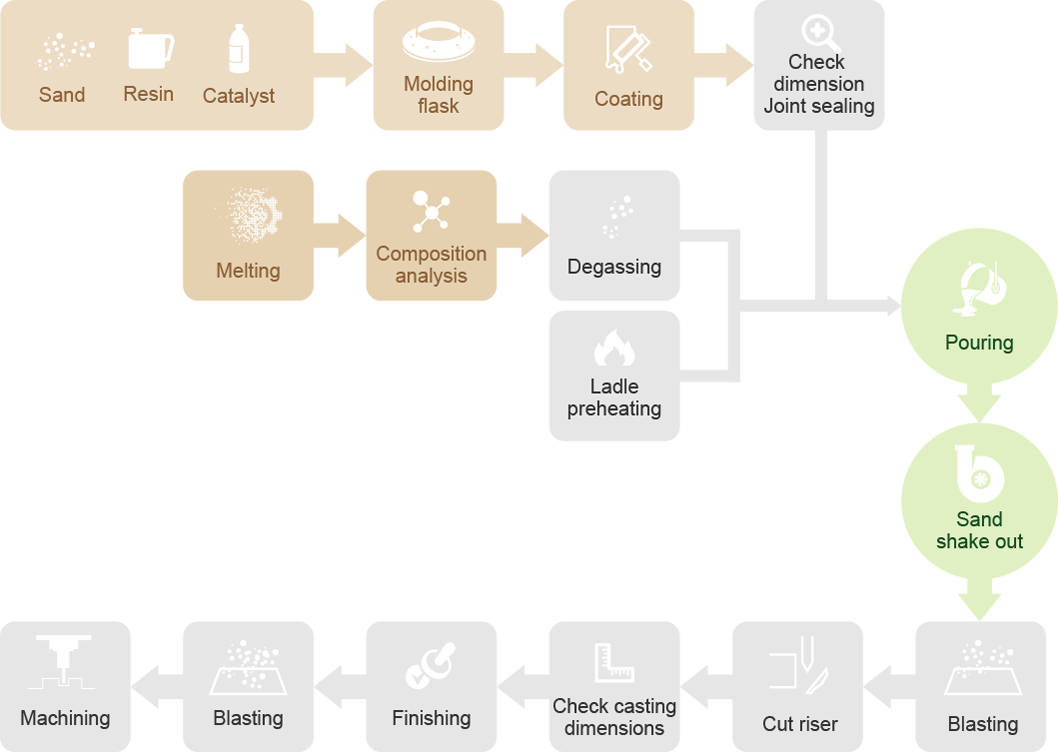

Furan sand casting process at TNGEC:

Flowchart of the Furan sand casting process at TNGEC

Furan sand casting process at TNGEC

- The mold is prepared by pouring sand into a mold cavity.

- The mold is closed and heated to a high temperature.

- The metal is melted and poured into the mold.

- The metal cools and hardens in the mold.

- The mold is opened and the casting is removed.

Applications of Furan Sand Casting Technology

Furan sand casting technology is a versatile process that can be used to create a wide variety of products, including:

- Automotive parts

- Machinery parts

- Oil and gas equipment

- Marine equipment

- Heavy industry equipment

TNGEC is a leading manufacturer of electric motor housings that are made using Furan sand casting technology. Our products are known for their high quality, precision, and durability. We offer a wide range of electric motor housings to choose from, and we are confident that we can meet your specific needs.

If you are interested in learning more about our electric motor housings, please contact us today at +84 914 765 250. We would be happy to answer any questions you may have.